faqs about push beam trolleys

What is the difference between a beam trolley and a beam clamp?

What is the difference between a beam trolley and a beam clamp?

A beam trolley allows a suspended hoist or load to travel along the beam for horizontal movement. A beam clamp creates a fixed attachment point on the beam flange and does not provide travel, making it suitable for stationary lifting only.

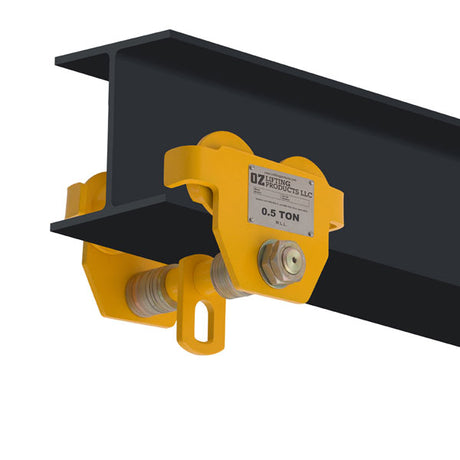

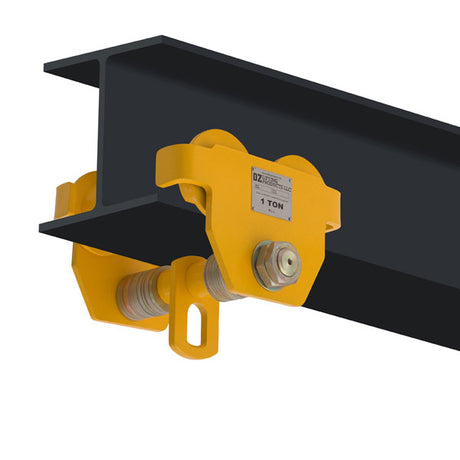

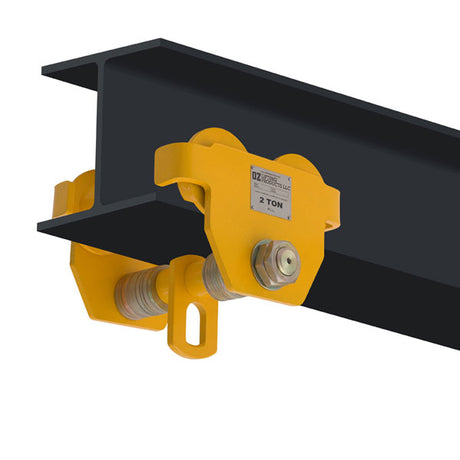

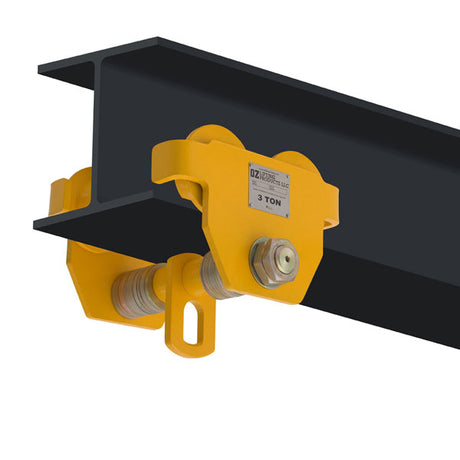

How do I choose the right load capacity for a beam trolley?

How do I choose the right load capacity for a beam trolley?

Select a beam trolley with a rated capacity that exceeds the maximum load you plan to lift, including the weight of the hoist and any rigging. Maintaining a safety margin helps support reliable operation and compliance with workplace safety practices.

Are push beam trolleys compliant with United States safety regulations?

Are push beam trolleys compliant with United States safety regulations?

Yes. Push beam trolleys supplied for use in the United States are designed to meet applicable OSHA workplace safety requirements and align with ASME B30 standards, which cover design, inspection, and safe use of overhead lifting equipment.

Can a push beam trolley be used with a chain hoist or electric hoist?

Can a push beam trolley be used with a chain hoist or electric hoist?

Yes. Push beam trolleys are commonly paired with manual chain hoists and electric hoists. Always verify that both the trolley and hoist have matching or compatible load ratings and mounting dimensions.

Is side loading a push beam trolley safe?

Is side loading a push beam trolley safe?

Side loading is not recommended. Beam trolleys are engineered for loads that hang vertically beneath the beam. Applying force from the side can damage wheels, deform the beam flange, and reduce the rated load capacity.

Can a push beam trolley be mounted on a curved beam?

Can a push beam trolley be mounted on a curved beam?

Most standard push beam trolleys are designed for straight beam applications. Curved or irregular beams may require specialized trolley designs or custom solutions to ensure safe operation.