In the post we will go over all the essential equipment for using with a chain block or any kind of electric chain hoist:

WHAT ARE THE DIFFERENT TYPES OF BEAM CLAMPS?

Some variations of clamps are used to lift, stack, and position beams and girders while others must not be used for lifting and are instead used as a suspension point on a beam for a hoist.

The beam clamps we will be looking at are used to attach lifting equipment, such as a hoist or chain block, to a suitable beam or gantry which is fit for purpose and that can have compatible capacities.

They are available in sizes to fit various beam widths, can be adjustable, can be used for temporary or permanent usage, and come in a variety of capacities and functions.

SAFE USE OF BEAM CLAMPS

Observe the following Dos and Don'ts to protect your safety and the longevity of your clamp:

DO:

-

Beam clamps should be inspected before being handled, used, or stored.

-

Verify that the supporting beam is suitable for the weight of the load and the equipment being used, is not twisted, and is not damaged.

-

Check that the clamp is centered over the load and that the beam/girder width is appropriate for the clamp.

-

If utilizing a hoist, be sure the hook is squarely above the load and the chain is not twisted.

-

Test the operation safely and check that the brakes are working, the path is clear, and the area is prepared.

DON’T:

-

Use clamps or any other lifting equipment made for other uses.

-

Make modifications to the clamp.

-

Throw or drop a clamp.

-

Force a clamp onto an unsuitable beam or hoist.

-

Leave a lifting operation unattended.

REMEMBER:

Most beam clamps are developed for use as a suspension point for a hoist and not for attachment onto a load that is being lifted.

COMPARE CLAMPS

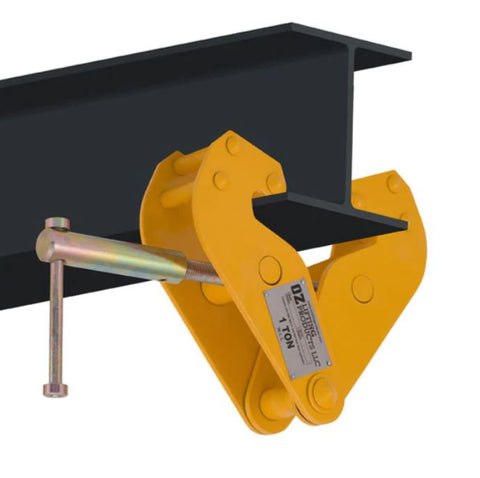

The OZ Beam Clamp

Available in capacities of 1 ton up to 10ton.

The OZ Beam Clamp is a robust all-steel, fully welded construction beam rigging clamp. Super quick adjustment to fit most I-Beams. Durable baked-enamel paint protection.

OZ Fall Protection Beam Clamp USA

Available in capacities of 1 ton up to 10ton.

This Fall Protection Series Beam Clamp is a robust all-steel, fully welded construction clamp which can be used to support a personal fall arrest system. This Beam Clamp is designed to withstand vertical fall arresting forces and complies with standards for fall protection.

OZ Stainless Steel Beam Clamp

Available in capacities of 1 ton and 2 ton.

The OZ Stainless Steel Beam Clamp has a sturdy, 304 stainless steel construction that resists corrosion

The adjustable flange width ranges from 2 15/16" to 9 1/16". It clearly identifies its use with a stainless steel ID tag.

SELECTING A TRAVEL TROLLEY

Beam travel trolleys come in a wide range of types with many options, including motorized or manual, push or pull, and various beam widths. A few crucial factors should be taken into consideration while deciding the kind of trolley to choose:

PUSH TROLLEYS

Push trolleys have a bottom flange and a set of wheels that allow them to move manually and horizontally on a level or tapered beam. If you plan to lift lighter weights, these are better since they will hold a chain block with a top hook or lug mounted suspension.

GEARED TROLLEYS

A geared trolley is the ideal option when precise placing of a greater load is required. A hand chain that has been looped and is attached to a sprocket makes up beam gear trolleys. When the hand chain is pulled, the sprocket moves the gears, allowing the wheels to move and moving the trolley in the other way.

ELECTRIC TROLLEYS

For weights weighing more than 1000 kg that need to be often lifted and transported over long distances, electric trolleys are especially advised.

SAFE USE OF BEAM TROLLEYS

Regardless of the sort of beam trolley you select, using it properly will ensure that you get the most use possible out of it, extend its life, and save you both time and money.

To guarantee proper handling and usage, follow these actions and avoid these pitfalls.

DO:

-

Trolleys should be handled with care and stored properly.

-

Before usage and storage, inspect and test trolleys and other lifting equipment.

-

Verify that the trolley width and wheel profile are appropriate for the track.

-

Make sure to fit and adjust the trolley to the width of the beam.

-

Ensure that the trolley, beam, and hoist's capacity are appropriate for the load being lifted.

-

The chain of the hoist should be long enough to hang about 2 feet above the operating level.

-

Always lock the adjustment bar before using it.

-

Clear the beam of any obstructions or debris.

DON’T:

-

Expose trolleys to corrosive chemicals, steam or water without checking the specifications.

-

Force the suspension hook onto the load bar.

-

Throw or drop a trolley.

-

Use a trolley with damaged wheel flanges.

-

Side load a trolley at an angle. This can bend the beam flange or trolley

-

Use a trolley on a beam that is not designed for use with a trolley.

-

Modify the trolley. This will void the manufacturer's warranty and compromise it’s safety.

-

Over-torque the trolley. This can cause bending of the adjustment rods.

HOW TO MAINTAIN A BEAM TRAVEL TROLLEY

Once you've chosen the ideal trolley, following these fast suggestions will make caring for it much easier:

EXAMINATION

Despite the fact that all lifting equipment is thoroughly checked before being sold in top shape, it is in your best interest to inspect your trolley before using it to make sure you are comfortable doing so. Check the following items:

-

The cargo doesn't weigh more than what the trolley, hoist, or beam can support.

-

The W.L.L. and ID number of the trolley are clearly visible.

-

All of the other components, including the side plates, suspension shackle, gears, and other parts, are free from wear, distortion, and damage.

-

The chain shouldn't be twisted and should be properly seated in the sprockets.

-

The locking mechanism should work as intended, the adjustment bar should be straight, and the threads should not be stretched or damaged.

STORING AND HANDLING

Trolleys should always be inspected after use and before being put away; they should be free of damage, dry, clean, and maintained in a clean, dry place to prevent rusting.

To prevent damage, operating chains, power controllers, and other attachments can be taken off and stored separately.

INSTALLING

Along with the advice provided in this blog article, the beam trolley and hoist's instruction manuals should be followed.

Verify that the trolley is adjusted to the correct width and that the track-appropriate wheels are on the trolley and that the track is level, has an even surface, and is equipped with sufficient end stops.

Make sure all nuts and bolts are tightened and that end stops are fastened.

MAINTENANCE

The hoist and any other equipment used with the trolley should also be maintained.

Regular lubrication of all moving parts is recommended.

Make sure the track is clear of all debris and lubricants by cleaning the wheels and the track.

Check the trolley and all related equipment frequently for wear, damage, loose fittings, distortion, and illegible labeling.

OZ Push Beam Trolley

The OZ Push Beam Trolley is a light weight robust construction beam trolley. Capacities from 0.5 ton up to 10 ton are available to choose from. The width adjustment mechanism makes this push beam trolley easy to install.

OZ Geared Beam Trolley

The OZ Geared Beam Trolley is designed for positive load positioning. Also it is a light weight robust construction geared beam trolley. Capacities from 1 ton up to 30 tons are available to choose from. The width adjustment mechanism makes this geared beam trolley easy to install.