Introduction:

Forklifts are a cornerstone in the logistical and warehousing operations across the United States. While these powerful machines enhance efficiency, their attachments - designed to handle a variety of tasks - bring additional safety considerations. This guide aims to shed light on the safe usage of forklift attachments, ensuring both productivity and safety in American workplaces.

Understanding Forklift Attachments:

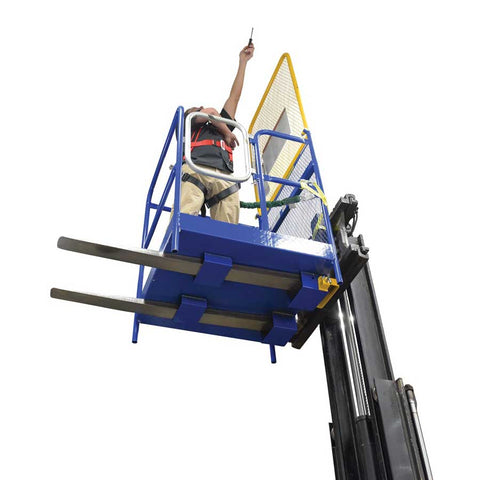

Forklift attachments are add-ons or modifications made to a standard forklift to enhance its functionality. Common attachments include side shifters, rotators, fork positioners, and clamps. While they increase versatility, each attachment alters the forklift's operating characteristics, including its load center and capacity.

Key Safety Considerations for Forklift Attachments:

1. Proper Attachment Selection: Choose attachments suitable for the specific task and load type. Using inappropriate attachments can lead to accidents.

2. Understanding Load Capacity: Attachments can change the forklift's load capacity. Always refer to the forklift’s data plate and adjust operations accordingly.

3. Training and Certification: Operators must be trained not just in forklift operation but also in the specific attachments they will be using.

Safety Practices for Operating Forklift Attachments:

- Regular Inspections: Inspect attachments for signs of wear or damage before each use.

- Secure Attachment: Ensure that the attachment is securely fastened to the forklift.

- Smooth Operation: Train operators to handle loads smoothly to avoid tipping.

Maintenance Tips for Forklift Attachments:

Consistent maintenance is crucial. This includes regular lubrication, checking for hydraulic leaks, and ensuring that all moving parts are in good working order.

Compliance with U.S. Safety Standards:

Ensure that all forklift attachments comply with standards set by the Occupational Safety and Health Administration (OSHA) in the U.S. Regular audits and compliance checks are essential for maintaining safety standards.

Conclusion:

The addition of attachments can make a forklift a versatile asset in any U.S. workplace. However, this versatility comes with the responsibility of ensuring safety. By selecting the right attachments, ensuring proper operator training, and adhering to regular maintenance and safety standards, businesses can reap the benefits of these tools while maintaining a safe work environment.